- #Mach3 and sheetcam for sale manuals#

- #Mach3 and sheetcam for sale 32 bit#

- #Mach3 and sheetcam for sale software#

- #Mach3 and sheetcam for sale Pc#

The third piece of the puzzle involves the CNC software.

#Mach3 and sheetcam for sale software#

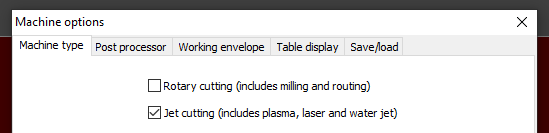

This code is used to tell the table software where to move the stepper motors. The second is CAM software which takes the design and turns it into “G-Code”. First off is a design program in order to create whatever it is that will be cut. The CNC system requires 3 different programs in order to make the magic happen.

#Mach3 and sheetcam for sale Pc#

So with the power supply, stepper motors, and PC all dealt with the next step was software.

#Mach3 and sheetcam for sale 32 bit#

The computer will only be running 1 piece of software and nothing else using the Windows 7 32 bit operating system. I figured as long as I could get all the bits to fit in the box and if I could find a place to plug in all the wires how could it possibly not work? Looks like my theory was correct, I was able to keep all the smoke contained within the components, nothing leaked out, electrons flowed and pixels were produced.

I have never actually built a computer and really have no idea what I am doing. The PC spec’d out as follows Intel Core i3 3.60GHz processor, Asus H81M-E motherboard, Kingston HyperX Fury Black 4GB RAM, Asus 24x DVDRW, coupled with a Kingston V300 120GB solid state hard drive. I stopped in at my local computer supply store and picked myself up a PC case and all the guts needed to get the electrons flowing. I opted to build my own PC to the specs dictated by CandCNC in order to ensure the Bladerunner will approve of the commanding officer. In my case the boss will be a dedicated computer running specific software to shout the orders to the stepper motors. Since the BladeRunner is only a power supply controlling some stepper motors it requires a commander. The Bladerunner also allows for Digital Torch Height Control (DTHC) which assists in the precision of the cut. stepper motors to move the X, Y, and Z axis (1 will be slaved to the Y axis). The highlights involve a power supply to run four 620 oz. There are way too many details to list about this unit, you can visit the link if you want to read up on it all. After much research I settled on CandCNC BladeRunner Dragon-Cut set up. Basically this involves some stepper motors attached to the tables gantry’s that allow for computer controlled movement of the torch. Next important piece of equipment in the CNC table build involves the tables X,Y,Z axis movement control. Creating plasma and molten metal is what it does best! 500” at 20 ipm (inches per minute) I can tell you, from experience, this unit is a work horse. This unit is spec’d to cut up to 1” thick steel and can do. I settled onto the Powermax45 for a number of different reasons and 1 significant reason was the ability to interface it with CNC to allow for torch height control. In my case I will be using my Hypertherm Powermax 45 unit which I purchased many years ago. What I will cover is the basic equipment involved in building the machine.įirst piece of equipment involves an actual plasma cutter. Not going to cover the basics in this blog. So for today I will simply set out the ground work which is necessary in order to understand what direction things are headed (yes…pun).įirst off, if you do not know what a CNC plasma table is then you can read about it here, or you can just Google it. I am not going to bore you with the entire game plan but instead I will let it all unfold in the blog.

The details involved in all the pre-planning are substantial. After having a few years to let the massive amount of information sink in I decided this winter season is the time to make this project happen.

#Mach3 and sheetcam for sale manuals#

I did much research many years ago which mostly involved reading manuals surrounding the CAD, CAM, and CNC operation and design. Over the past 4 years I have explored the idea of building a CNC plasma table. I have many ideas stored in my database, the one that rests upon my neck, and it was just a matter of choosing something. It allowed me to enjoy 2000km worth of riding this summer which included participation in the 2014 Distinguished Gentleman’s Ride.įor the winter season of 2014-2015 a new project is in order.

It was a good project that resulted in great success. Last winter I was able to occupy my time completing my 1965 CB160 Café Racer build. Winter fertilizer has been applied, trees and bushes have been pruned, sprinkler system has been blown out, and the gas yard equipment is set for winter servicing and storage. The past couple weekends have been spent putting the yard to bed. As the colder temperature and the snow begin to sink in as an unstoppable reality the planning for hibernation is inevitable. So winter is approaching which always signals time for change.

0 kommentar(er)

0 kommentar(er)